English Martyrs Catholic School, Hartlepool

Client: English Martyrs Catholic School | Location: Hartlepool | Specification of Work: Flat Roofing and Roof Refurbishment | Project Length: 10 Weeks

The Project

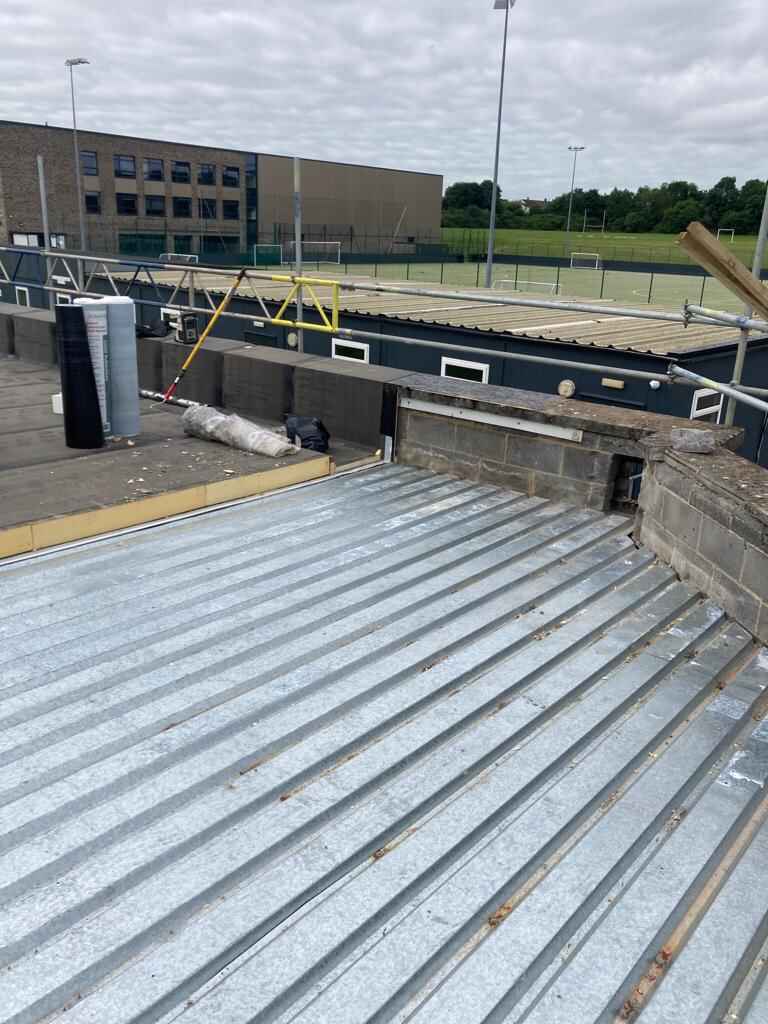

Strip all existing waterproofing and install a new SIGnature Bituminous Membrane warm roof system, this included a Tapered Insulation system to address poor falls, new outlets and drainage, correcting poor details and new rooflights.

Client Problems:

The client had many existing issues with the current condition of the roof. A specification and detailed inspection highlighted the following issues that were discovered.

- Large areas of single ply had been repaired with liquids as a temporary measure, it was suspected that many of the leaks occurring were due to the poor perimeter capping.

- The design of chute outlets were allowing water to ingress due to capillary reaction.

- The large barrel vault light was starting to fail, which appeared to be detailing issues with the single-ply system.

- Part of the roof was the original roof coverings and was circa 30 year plus old and was starting to fail in various areas.

- Some of the rooflights were not to current build standards and were considered fragile and unsafe.

- An overlay membrane had been poorly installed on one roof, and details were not to British standards or good codes of practice, which had lead to early failure of the upstand detail.

Solution:

An initial risk assessment was carried out by both Roofclad Systems as well as an independent health and safety consultant to identify areas of risk for this installation and to itemise the correct PPE requirement for this site and these products. Scaffolding was erected around the site using a fence system – the scaffolding was anchored into the brickwork so that there was no scaffolding that could be accessed from ground level and the scaffolding contractor was required to provide evidence of pull-out tests to ensure the scaffolding was adequately anchored to the building.

The existing roof structure had included just 15mm of insulation – the replacement roof was designed to meet current Building Regulations, requiring a u-value of 0.18W/m2K.

Insulation manufacturer Tapered Plus was called in to provide a detailed specification, carrying out the calculations to ensure that the tapered insulation required to create the fall did not compromise on the thermal efficiency of the roof.

The system used for the project was the SIGnature torch on waterproofing system from SIG.

This project included an overlay solution (overlay was considered a good treatment for the felted sections of the roof) while areas that had previously used a single ply membrane were stripped back to the structural deck (metal / timber) and replaced.

The SIGnature torch on waterproofing system comprised of:

SIGnature Fast Drying Primer

Vapour control layer – SIGnature Torch on VCL (metal lined) with a polyester reinforced aluminium-cored SBS modified bituminous membrane to be attached by torching.

Tapered Board insulation – PIR insulation board attached using PU Adhesive. Insulation board manufactured by Tapered Plus

Underlay: SIGnature Underlay 25, a polyester reinforced SBS modified bitumen membrane.

Cap Sheet: SIGnature Capsheet – polyester reinforced self-finished SBS modified bitumen membrane with a thermo-fusible film to the underside.

The complexity of this project was primarily down to the circular and semi-circular shape of the roof surfaces. All insulation and felts needed to be accurately trimmed to match the circumference of the roof. This was achieved by careful measurement of the circumference which was then translated onto the surface of the roofing material using a compass.

The other issue with the circular roofs was that the original roof deck had not been laid to falls – which explained why there had been significant pooling of water on the surface, accelerating the degradation of the roofing membrane. To remedy this, the falls were incorporated into the insulation layer, so the insulation sheets tapered in their thickness for a front-to-back fall, encouraging the required surface drainage. The deck of the more regular shaped roof areas was laid to fall appropriately, so the new roof covering simply had to follow the design of the substrate.

As the project commenced, new issues arose and had to be dealt with. For example, when the scaffolding was installed, allowing for close inspection of the fabric of the building, it became clear that in one section of the building the top courses of brickwork were in poor condition. Roofclad Systems instructed a brickwork contractor to replace the top courses of bricks – causing the schedule of work to be re-drafted to ensure the project remained on schedule.

Inspection of the perimeter upstands and coping stones also revealed a significant deterioration in the masonry. It was therefore concluded that the best (and most aesthetically pleasing) solution was to fully encapsulate these details: they were boarded, covered with timber and then treated with the underlay and cap-sheet, blending with the rest of the roof area. The result is satisfyingly clean with true angles giving a great aesthetic.

The majority of the project work took place during the school holidays during a particularly wet summer with a further four weeks when the building was in use, which required additional health and safety considerations to be implemented. Despite the challenging weather conditions Roofclad Systems were still able to complete this project on time.

We are proud to say that this project has been nominated in the Reinforced Bitumen Membranes category at this years NFRC awards.